Products

News

- How to Install AAC Conductor

- Power cable current carrying capacity

- Guide on Low Voltage Aerial Bundling Cables(ABC Cab

- Guide to Electrical Insulators

- The difference between 3 + 2 and 4 + 1 on wires and

- What are the cable accessories?

- AWG (American Wire Gauge) to MM2 Conversion

- Cable Short Circuit Current Calculate

- Overhead conductor,poles,and gold fittings design

- OPGW Cable Line Design Several Key Issues[2]

Contact us

E-Mail:info@dosensecable.com

Phone:+8613073786551

Tel:+8613073786551

Add:Zhengzhou, Henan,China

Medium Voltage Cable Heat Shrink Terminals

Brand:Dosense Cable

Category:Products

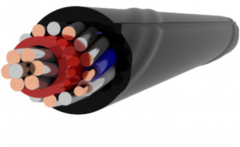

Materials Used in Medium Voltage Cable Heat Shrink Terminals: Heat Shrinkable Tubing: This is the main component of the terminal and provides insulation and sealing. Its typically made from cross-linked polyolefin or other heat shrinkable p...

Materials Used in Medium Voltage Cable Heat Shrink Terminals:

Heat Shrinkable Tubing: This is the main component of the terminal and provides insulation and sealing. It's typically made from cross-linked polyolefin or other heat shrinkable polymers.

Adhesive: The heat shrink tubing often includes an adhesive lining that melts and flows when heated, forming a tight seal around the cable and conductor.

Stress Control Tubes: These are used to evenly distribute electrical stress and prevent corona discharge at the interface between the cable insulation and the terminal.

Mastic: Mastic is a viscous sealing material applied to enhance moisture resistance and provide additional insulation. It's often used in conjunction with stress control tubes.

Insulating Tape: Insulating tape may be applied over the terminal for further protection and sealing.

Typical Technical Data Associated with Medium Voltage Cable Heat Shrink Terminals:

Voltage Rating: Specifies the range of voltages that the terminal is designed to handle, usually expressed in kilovolts (kV). Common voltage ratings for medium voltage terminals might be 6 kV, 11 kV, 20 kV,or 33 kV.

Temperature Range: Indicates the operating temperature range that the terminal can withstand without degradation of its electrical or mechanical properties.

Shrink Ratio: Specifies how much the heat shrink tubing will shrink when heated. For example, a shrink ratio of 3:1 means the tubing will shrink to one-third of its original size.

Dielectric Strength: This refers to the maximum electric field that the insulation material can withstand without breaking down. It's typically measured in volts per unit thickness (e.g., kV/mm).

Tensile Strength: Indicates how much force the terminal can withstand before breaking. Expressed in pounds per square inch (psi) or Newtons per square millimeter (N/mm²).

Elongation at Break: Measures how much the terminal can stretch before breaking, expressed as a percentage.

Water Absorption: The amount of water the terminal material can absorb over time, which can affect its insulating properties.

Flame Retardancy: Some terminals may be designed to have flame-retardant properties to enhance safety.

- Previous:No

- Next:No

Related Products

info@dosensecable.com

info@dosensecable.com

Tel:

Tel:  Address: Zhengzhou, Henan,China

Address: Zhengzhou, Henan,China